Carbon Black PE Conductive Compounds for Industrial Packaging Solutions The In Liner PE Bags for Type C FIBC Bulk Bag

Product Details:

| Place of Origin: | China |

| Brand Name: | SUGO ESD PLASTICS |

| Certification: | ISO9001:2015; ISO14001:2018; ISO45001:2018 |

| Model Number: | L2360 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 kgs |

|---|---|

| Price: | USD/KG |

| Packaging Details: | 25Kg/ Vacuum Alum Foil Bag, 40 Bags/Pallet, Wrapped arround with shrinkage film |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 1500Tons Monthly |

|

Detail Information |

|||

| Carrier: | Polyethylene | Conductive Agent: | Carbon Black |

|---|---|---|---|

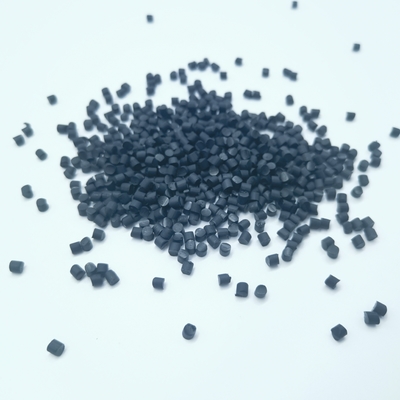

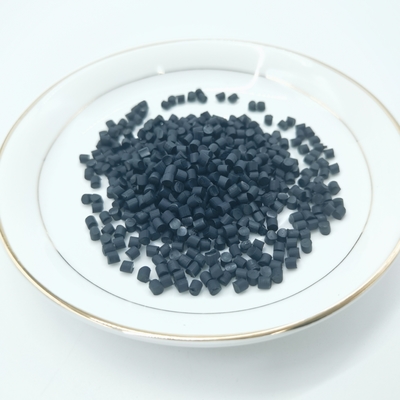

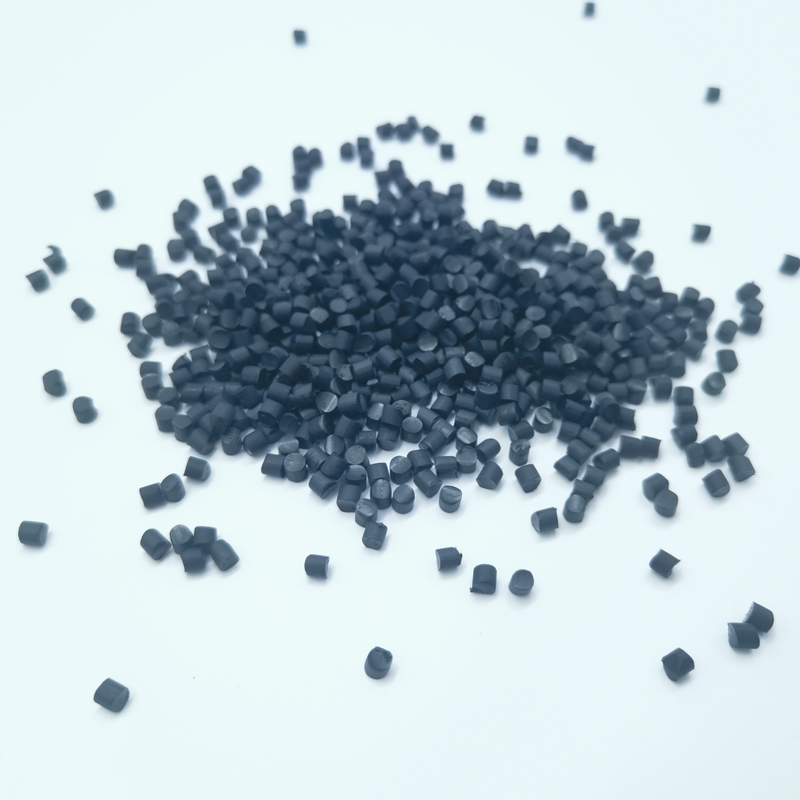

| Appearance: | Black Pellets | ESD Value: | 10^3~5 Ohms/sq |

| Content Of Carbon Black: | 18-25% | Tensile Strength: | > 18Mpa (ASTM D638) |

| Elongation At Break: | >350% | Thickness Range: | 50–200μm |

| Application: | Conductive In Liner Type C Bags | Regulatory Compliance: | RoHS, REACH, And FDA Food-contact Safe Certifications (optional) |

Product Description

Carbon Black PE Conductive Compounds for Industrial Packaging Solutions The In Liner PE Bags for Type C FIBC Bulk Bag

Product Overview

Our advanced Carbon Black PE Conductive Compounds are engineered to deliver exceptional electrostatic protection

and mechanical durability, making them the ideal material for manufacturing large-scale or type C in liner PE

conductive bags. By integrating high-purity conductive carbon black with premium blown-film grade polyethylene (PE),

we have developed a proprietary compound that ensures stable conductivity, superior tensile strength, and unmatched

flexibility.

This innovative material effectively dissipates static charges, preventing spark risks when handling powders, granules,

or other friction-prone substances.

![]()

Key Features

- Optimized Conductivity: Precision-engineered carbon black dispersion guarantees consistent surface resistivity

(10^3~5 Ω/sq), meeting ASTM D257 standards for static control.

2. Exceptional Mechanical Properties:

-

- High tensile strength (>18 MPa) and elongation at break (>350%) for rugged durability.

- Superior impact resistance and tear resistance, ensuring reliable performance in demanding logistics environments.

3. Processability: Compatible with blown film extrusion systems, enabling seamless production of large-format bags

(up to 2000mm width) with uniform thickness.

4. Chemical & Environmental Resistance: Withstands exposure to oils, solvents, and temperature fluctuations (-30°C to

+60°C) without degradation.

5. Regulatory Compliance: RoHS, REACH, and FDA food-contact safe certifications (optional).

Applications

- Industrial Packaging: Safe containment of combustible powders (e.g., chemicals, pharmaceuticals, metal oxides).

- ESD Protection: Ideal for electronics, automotive components, and aerospace materials requiring anti-static handling.

- Agricultural & Mining: Dust-free storage and transport of granular fertilizers, minerals, and construction materials.

![]()

![]()

Why Choose Our Conductive Compounds?

- Custom Formulations: Tailor resistivity levels, color, and additive packages to meet specific industry requirements.

- Cost Efficiency: Reduces material waste through stable extrusion performance and consistent film quality.

- Global Compliance: Adheres to international standards for static control packaging (IEC 61340, NFPA 77).

- Sustainability: Recyclable and compatible with eco-friendly additive options.

Technical Specifications

Quality Assurance

Every batch undergoes rigorous testing for conductivity stability, mechanical performance, and thermal resistance.

Our ISO 9001-certified manufacturing process ensures traceability and consistency, empowering customers to achieve

zero-defect production in critical packaging applications.

Global Supply & Technical Support

With warehousing facilities in Asia, Europe, and North America, we offer JIT delivery and dedicated R&D collaboration

to optimize material performance for your equipment and end-use needs.

Contact Us Today

Elevate your industrial packaging solutions with our Carbon Black PE Conductive Compounds. Let our experts help you

design the perfect anti-static material for your application.

Shipping Information

Main Export Markets

![]()

![]()