200 - 300 Ohms PE Conductive Compounds For Wire And Cable Shielding Layer

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | SUGO |

| Certification: | ISO9001:2015; ISO14001:2015; ISO45001:2018 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 Kgs |

|---|---|

| Price: | USD/KG |

| Packaging Details: | 25Kg/Bag, 40 Bags/Pallet, Wrapped With Shrinkage Film |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1100 Tons/Monthly |

|

Detail Information |

|||

| Baxic Resin: | PE | Application: | For Wire And Cable Shielding Layer |

|---|---|---|---|

| Surface Resistivity: | 200-300 Ohms | Process Grade: | By Injection |

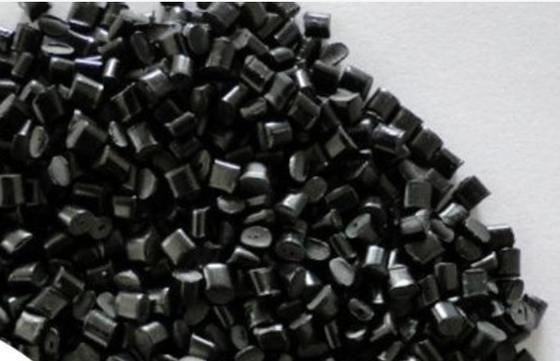

| Appearance: | Black Pellets | Feature 1: | Environmental Protection |

| Feature 2: | Non-toxic | Feature 3: | Excellent Low Temperature Resistance |

| Highlight: | 300 Ohms Conductive Compounds,200 Ohms Conductive Compounds,Conductive PE For Cable Shielding Layer |

||

Product Description

PE Conductive Compounds Special For Wire And Cable Shielding Layer

What is the special material for wire and cable shielding?

Do you know what kind of plastic material is used for the special material of wire and cable shielding?

Let me take you to find it out.

The wire and cable industry is the second largest industry in China after the automobile industry, and

the product variety satisfaction rate exceeds 90% in my country's domestic market. A shielded cable is

a transmission line that uses a metal mesh braid to wrap the signal line.

The conductive anti-static polyethylene (PE) plastic has the characteristics of environmental protection,

non-toxic and tasteless, excellent low temperature resistance and stable chemical properties. Good ele

-ctrical insulation. Conductive anti-static PE plastic can be processed into wire and cable sheaths, films,

injection molding products, etc., so conductive anti-static PE plastic is the best choice for cable shielding

material selection.

The development of the cable industry is closely related to the development of my country's industrial

economy, especially the development of the information industry. With the acceleration of power grid

construction, especially the investment of UHV projects, the demand for wire and cable materials is

gradually increasing. Therefore, the development of our conductive anti-static PE plastics will also increase.

I hope my introduction will help you understand!

More Details:

| Basic Resin | PE |

| Description | PE Conductive Compounds Special For Wire And Cable Shielding Layer |

| Surface Resistivity | 200-300 ohms |

| Appearance | Black Pellets |

| Grade | Injection or Extrusion |

| Application | Suitable for preparing conductive PE injection molding, extrusion, wire and cable shielding layer, etc. |

Application Samples:

![]()