30% Elongation ABS Stainless Steel Fiber Conductive Compounds

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | SUGO |

| Certification: | ISO9001:2015; ISO14001:2015; ISO45001:2018 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 kgs |

|---|---|

| Price: | USD/KG |

| Packaging Details: | 25Kg/Bag, 40 Bags/Pallet, Wrapped With Shrinkage Film |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Tons Monthly |

|

Detail Information |

|||

| Basic Materials: | ABS Resin | Additives 1: | Stainless Steel Fiber |

|---|---|---|---|

| Surface Resistivity: | <10 Ohms | Feature 1: | Permanent Stable Electrical Conductivity |

| Feature 2: | Good Processability | Feature 3: | Environmental Protection |

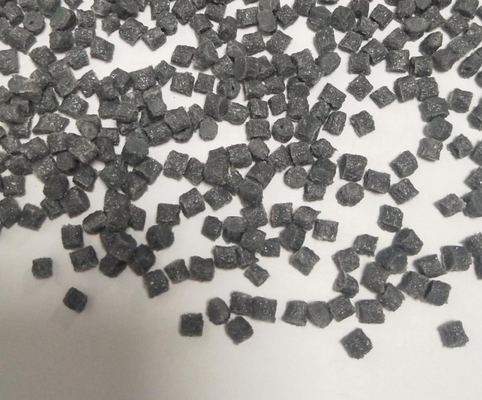

| Appearance: | Black Pellets | Tensile Strength: | 35 Mpa |

| Flexural Strength: | 50 Mpa | Elongation: | 30% |

| Highlight: | ABS Stainless Steel Fiber Conductive Compounds,30% Elongation Conductive Compounds,Conductive ABS Stainless Steel Fiber |

||

Product Description

ABS Conductive Stainless Steel Fiber Compounds

Product description: This product is made by ABS as basic plastic, blended with stainless steel fiber

and other additives. By adjusting different material ratios during processing, the effect of electrical con

-ductivity is increased while maintaining the original characteristics of ABS plastic. Our company's steel

fiber conductive ABS has very good mechanical properties and physical properties, and is currently the

most competitive product in the industry.

Features: Permanent stable electrical conductivity, good processability and surface appearance, green and

environmental protection.

Scope of application: All kinds of ABS products with conductive and anti-static requirements, extruded

sheets, plates, electrical enclosures, capacitive pens, etc.

How to use: Feeding directly, injection or extrusion temperature is 220-250℃.

Drying conditions: drying at 100-110°C for about 2 hours.

| ITEM | ASTM | Test Condition | Unit | Values |

| Surface Resistivity | -- | -- | Ω | ≦10Ω |

| Tensile Strength | D638 | 50 mm/min | Mpa | 35 |

| Flexural Strength | D790 | 20 mm/min | Mpa | 50 |

| Flexural Modulus | D790 | 20 mm/min | Mpa | 2900 |

| Elongation | 50 mm/min | % | 30 | |

| IZOD Notch Impact Strength | D256 | Sample Size | kJ/m2 | 15 |

| 80×10×4mm, IZOD Deep:2 mm |

||||

| MFI | -- | 220℃/5Kg | g/10min | 3 |

Application Samples: ABS Electrical Enclosures

![]()