Green Conductive Polyphenyleneoxide For Static Sensitive IC Trays

Product Details:

| Place of Origin: | DONGGUAN, China |

| Brand Name: | SUGO |

| Certification: | ISO9001:2015; ISO14001:2015; ISO45001:2018 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 200 kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg per bag, paper bag with inner PE layer |

| Delivery Time: | 3-7 days |

| Payment Terms: | 100% T/T before shipment, or LC at sight |

| Supply Ability: | 1000TONS/M |

|

Detail Information |

|||

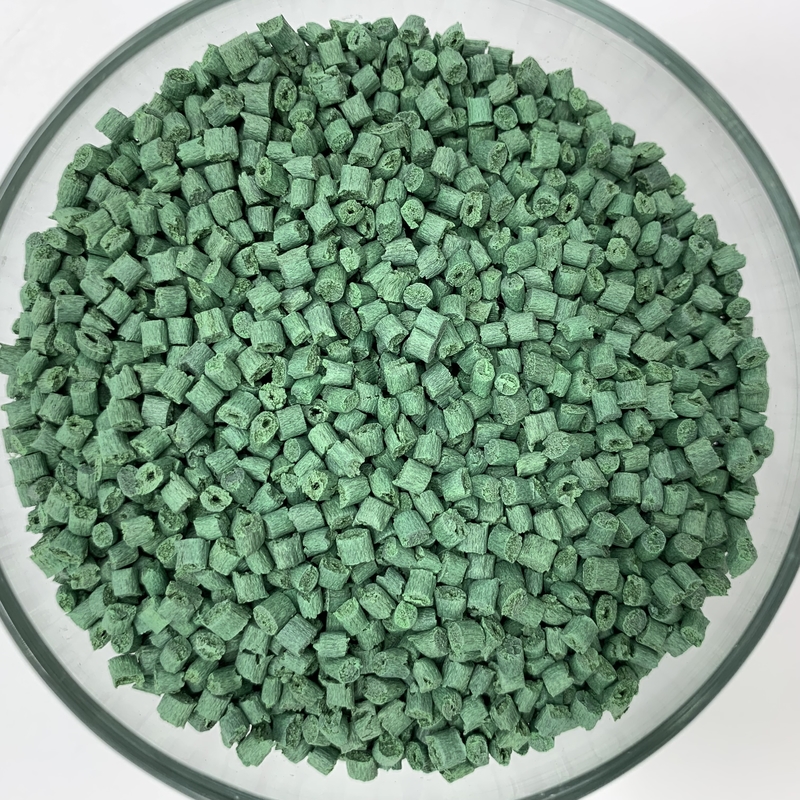

| Product Name: | Conductive PolyphenyleneOxide | Appearance: | Round Granular |

|---|---|---|---|

| Shape: | Pellet, Granule,Particle | Advantage: | High Temperature Resistance, Dimensional Stability, High Strength, High Rigidity |

| Pigment: | Antistatic Pigments | Usage: | IC Trays |

| Highlight: | Conductive Polyphenyleneoxide,Green Polyphenyleneoxide,ROHS round granular Conductive Compounds |

||

Product Description

Green conductive PolyphenyleneOxide Special Effect for static sensitive IC trays

SUGO company is a Professional provider for Conductive and Antistatic plastics material in China.

The MPPO is filled with carbon fiber for electrically conductive effection.

The amazing thing is now, color can be customize, such as green, purple, blue, grey, THE surface resistance can keep the same.

Advantages than other suppliers:

1) Stable resistance between 10^3-10^5 ohm/sq.

2) Can be colored.

3) Easy molding

4) Low cost

Applications

- Electronic packaging

- IC trays

- Injection Molded Parts.

-

Anti-static grade POM

| Product name | MPPO filled with carbon fiber added for electrically conductivity |

| Color | Green, black, grey color is available |

| Advantage | High temperature resistance Dimensional stability High strength good appearance effect |

| Packing | 25kg/bag (also customizable) |

Why choose us

(1) Easy to handle and disperse, no dust

No grinding is necessary. Under high-speed dispersion, basic painting occurs between 30 and 45 minutes. It is enough to have high-speed dispersion equipment without any need to invest large amounts of money to buy grinding equipment. It can be produced at any scale, from mass production to the laboratory. In addition, the inventory can be significantly reduced. Also, when cleaning and changing colors, it will be easier to clean the dispersion equipment.

(2) Available from unique technical merits and the most complete humidity of the pigment

With the techniques, our pigment will make the carrier resin more humid. Therefore, it will give more luster and better transparency. As a result, foam and adhesion are reduced due to poor pigment moisture.

(3) The best stability

The continuous quality has been significantly improved between one batch of merchandise and the other and also the stability of reserved colors. In addition, the cost of quality inspection is reduced.