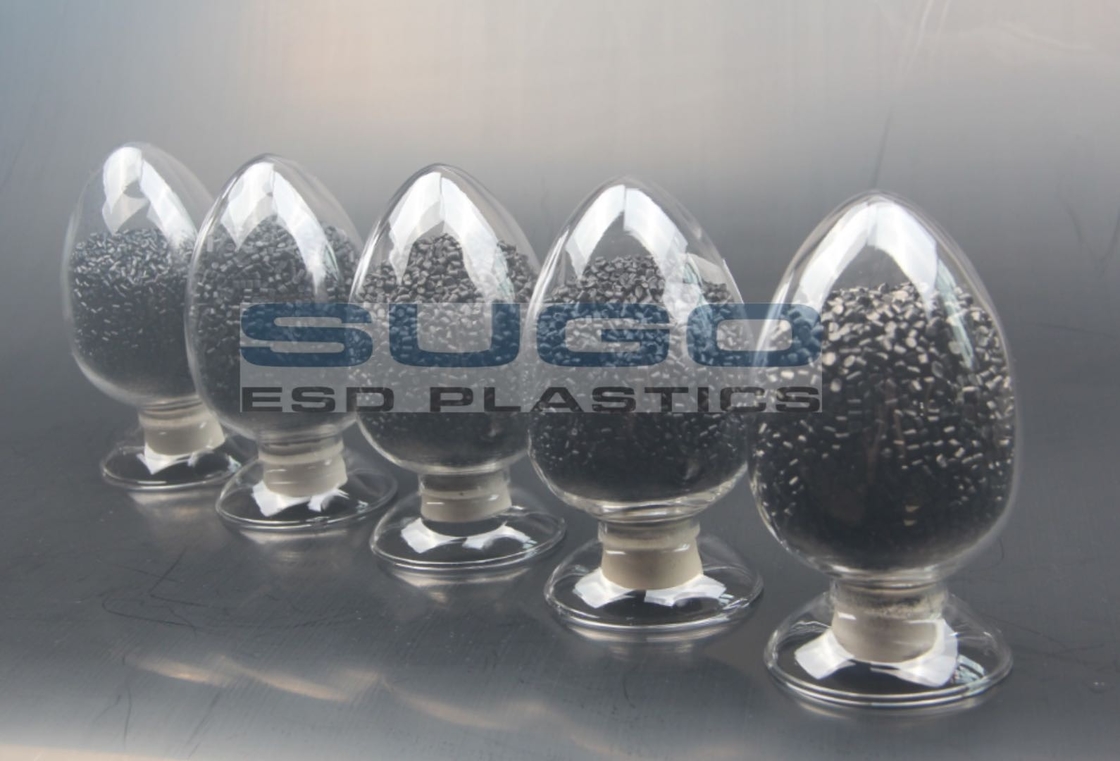

Polypropylene Conductive Masterbatch For PP Hollow Sheet

Product Details:

| Place of Origin: | DONGGUAN, China |

| Brand Name: | SUGO |

| Certification: | ISO9001:2015; ISO14001:2015; ISO45001:2018 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 200 kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg per bag, paper bag with inner PE layer |

| Delivery Time: | 3-7 days |

| Payment Terms: | 100% T/T before shipment, or LC at sight |

| Supply Ability: | 1000TONS/M |

|

Detail Information |

|||

| Product Name: | Antistatic Functional Masterbatch | Color: | Black |

|---|---|---|---|

| Compatibility: | PE.HDPE.LDPE.PP | Advantage: | High Content Of Conductive Filler,Good Dispersion Performance |

| Form: | Pellet | Usage: | E.Eindustry, Package Industry |

| Highlight: | Polypropylene Conductive Masterbatch,Antistatic Conductive Masterbatch,shoreA 95 Polypropylene Masterbatch |

||

Product Description

High Conductive PP masterbatch Excellent Dispersion For PP hollow Sheet

With our stringent quality policy, we have been able to meet requirements of the clients with a commendable gamut of Additive Masterbatches. This offered gamut is developed by making use of supreme quality required basic material in line with the illustrated parameters of the industry. Product which we offer effectively improves heat conduction property of the plastic which results in minimizing moulding period, tightness and rigidity. Our valued clients can avail the offered products in both customized and standard forms as per their requirement.

Advantage:

High content of conductive filler,Good dispersion performance

Electric conductivity; high impact, heat resistant, low-temperature resistant

Features:

Ability to withstand high temperature

Precisely processed

High strength

| Product Name | Conductive materbatch for polypropylene |

| Material | PP, carbon black |

| Color | balck |

| Hardness | shoreA 95 |

| Density | 1.05 |

| Tensile strength | ≥25Mpa |

| Elongation at break | 20% |

| Brittleness temperature | -20~80℃ |

| Advantage | Electric conductivity; high impact, heat resistant, low-temperature resistant |

| Character | migration resistance, durable, acid, anti-UV, Non-toxic, cost-effective |

Why choose us

(1) Easy to handle and disperse, no dust

No grinding is necessary. Under high-speed dispersion, basic painting occurs between 30 and 45 minutes. It is enough to have high-speed dispersion equipment without any need to invest large amounts of money to buy grinding equipment. It can be produced at any scale, from mass production to the laboratory. In addition, the inventory can be significantly reduced. Also, when cleaning and changing colors, it will be easier to clean the dispersion equipment.

(2) Available from unique technical merits and the most complete humidity of the pigment

With the techniques, our pigment will make the carrier resin more humid. Therefore, it will give more luster and better transparency. As a result, foam and adhesion are reduced due to poor pigment moisture.

(3) The best stability

The continuous quality has been significantly improved between one batch of merchandise and the other and also the stability of reserved colors. In addition, the cost of quality inspection is reduced.

Dongguan SUGO PlasticsTechnology Co., Ltd. was officially recognized as the National High - tech Enterprise in 2017 and is a famous ESD, condudtive and antistatic plastics material manufacturer in China. We provide a complete range of CONDUCTIVE and/or ESD plastic material well known for our superb quality and competitive price. Since 2001, we’ve specialized in the R&D, manufacturing and sales of modified engineering plastics. And our name is CNTPE (SUHENG) at that time. Now, the company CNTPE is still exist and in 2012, we set up SUGO. SUGO means inspire, creative new material all over the world to be with safe and respect for future and environment. For so many years, "let electrostatic under control" has been our unchanging mission. Now, we are one of the leading manufacturers creating ESD protection material that bring you a reliable and flexible solutions.