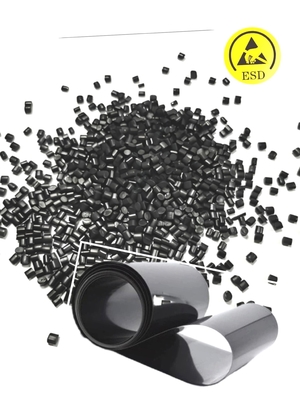

Conductive Carbon Black PS Materbatch or Concentrate Used For Conductive and Disspative PS Thermoforming Sheet, Dosage 32~36% gives ESD Value 10^3~9 ohms/sq

Product Details:

| Place of Origin: | China |

| Brand Name: | SUGO ESD PLASTICS |

| Certification: | ISO9001:2015; ISO14001:2018; ISO45001:2018 |

| Model Number: | TH3046A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 kgs |

|---|---|

| Price: | USD/KG |

| Packaging Details: | 25Kg/Bag, 40 Bags/Pallet, Wrapped arround with shrinkage film |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T, D/A, Western Union, MoneyGram |

| Supply Ability: | 800 Tons Monthly |

|

Detail Information |

|||

| Carrier: | High Impact Polystyrene Resin | Color: | Black Only |

|---|---|---|---|

| Surface Resistivity Of Masterbatch: | 30-50 Ohms/sq | Dosage For Disspative PS Sheet: | 32% Gives 10^6~9 Ohms/sq |

| Dosage For Conductive PS Sheet: | 36% Gives 10^3~5 Ohms/sq | Application: | Conductive And Dissipative PS Thermoforming Sheet |

| Main Market: | Asia And Europe | Production Capacity: | 800tons / Month |

| Improved Generation: | 5th | Glossy: | Matte |

Product Description

Conductive Carbon Black PS Materbatch or Concentrate Used For Conductive and Disspative PS Thermoforming

Sheet,Dosage 32~36% gives ESD Value 10^3~9 ohms/sq

Products Description

TH3046A is a high performance conductive PS masterbatch, which has been optimized for 5 times, and now achieve much better dispersion ability than previous generation.

| Model Number | TH3046A | ||||

|---|---|---|---|---|---|

| Brand Name | SUGO ESD PLASTICS | ||||

| origin | China | ||||

| Small Orders | Accepted | ||||

It belongs to ESD Materials.

![]()

Most improved point is that this item solved every problem for a PS sheet manfuacturer who is even a new to produce ESD sheet for the first time.

Product Introduction

ESD Materials includes both compounds and concentrate (masterbatch).

Our PS Conductive Masterbatch is a cutting - edge solution designed specifically for the extrusion production of conductive and anti - static PS sheets used in thermoforming applications. Engineered with precision, this masterbatch is the key to achieving superior electrostatic control in your PS sheet manufacturing process.

This is a conductive thermoplastic concentrate based on polystyrene.

It is used to lower the static decay time and surface resistivity of polystyrene resins to produce ESD PS sheet,

It imparts a long-lasting antistatic property.

The compatibility, dispersibility and stability of antistatic agent for Polystyrene are more outstanding than regular antistatic agent, and the physical properties of this resin show minimal change.

Using 35-36% gives surface resistivity on PS sheet of 10^3~5 ohms/sq.

Key Features

- -Exceptional Conductivity and Anti - Static Properties

- Our masterbatch is formulated with advanced conductive additives, enabling the production of PS sheets with outstanding electrostatic dissipation capabilities. This effectively prevents the build - up of static charges, which is crucial in applications where static electricity can cause product damage, dust attraction, or operational disruptions.

- Optimal Compatibility

- It has been carefully developed to have excellent compatibility with various grades of polystyrene (PS) resins commonly used in extrusion processes. This ensures uniform dispersion during the extrusion process, resulting in consistent conductive and anti - static performance across the entire PS sheet.

- Reliable and Stable Performance

- The PS Conductive Masterbatch maintains its performance integrity under a wide range of processing conditions. Whether it's different extrusion temperatures, screw speeds, or production volumes, you can count on our masterbatch to deliver reliable results batch after batch.

Dosage Instruction:

Structure of HIPS Sheet: 3 layers ABA structure, top and bottom layers with function of ESD protection

|

Dose of TH3046A |

Dose of HIPS Virgin |

S/R after extrusion | Dose of SBS |

| 32% | 68% | 1*10E6~9 ohms | 4% |

| 38% | 62% | 1*10E3~5 ohms | 0% (no need) |

Structure of HIPS Sheet: mono layer structure, passed the ESD value test of volume resistivity

|

Dose of TH3046A |

Dose of HIPS Virgin |

S/R after extrusion | Dose of SBS |

| 30% | 66% | 1*10E6~9 ohms | 4% |

| 36% | 64% | 1*10E3~5 ohms | 0% (no need) |

Pre-drying conditions: 90°C by 4 hours

Process Temperature: 190~220 °C

Applications

- Electronics Packaging

- Ideal for manufacturing PS sheets used to package electronic components such as semiconductors, circuit boards,

and sensitive electronic devices. The conductive and anti - static properties of the PS sheets protect these

components from electrostatic discharge (ESD), which can cause irreversible damage.

1. Conductive Thermoforming HIPS Sheet, ESD Value 10^3-5 ohms/sq

2. Dissipative Thermoforming HIPS Sheet, ESD Value 10^6~9 ohms/sq

![]()

![]()

- Industrial Packaging

- For packaging industrial products like precision machinery parts, optical components, and automotive electronics, the PS sheets made with our conductive masterbatch provide reliable protection against static - related issues.

Technical Specifications

Matrix Resin: High - Impact polystyrene (HIPS)

Conductive Filler: Composed of high - efficiency conductive materials, carefully selected to ensure optimal performance.

Appearance: Uniform pellet - shaped particles, easy to handle and mix with PS resins

Particle Size: O/D 3-4mm, Precise and consistent particle size distribution, promoting even dispersion during extrusion

![]()

Usage Instructions and Performance Data

Dosing Recommendations

- For achieving a surface resistivity of 10^6 - 10^9 ohms/square, a dosage of 30-32% of our PS Conductive Masterbatch in the PS resin blend is recommended.

- When a lower surface resistivity of 10^3 - 10^5 ohms/square is required, a dosage of 36-38% is optimal.

Mixing Process

- Thoroughly blend the masterbatch with the PS resin using a high - shear mixer. This ensures that the conductive particles are evenly distributed throughout the resin matrix, which is crucial for consistent performance.

Extrusion Process of ESD PS Sheet

- Feed the well - mixed resin - masterbatch blend into the extrusion machine. Standard extrusion parameters for PS

sheets can be applied, but minor adjustments may be needed depending on the specific equipment and production

requirements.

![]()

- Stringent Quality Control

- We implement a comprehensive quality control system at every stage of production, from raw material sourcing to

the final packaging of the masterbatch. Each batch is rigorously tested to ensure it meets our strict quality standards

and customer requirements.

![]()

- Certifications and Compliance

- Our products comply with international quality and safety standards, giving you the confidence that you are using a

reliable and compliant product. Comply with RoHS and REACH requirement.

If you have any inquiries or are interested in placing an order, please don't hesitate to contact us . We arededicated to

providing you with top - notch products and professional service to support your PS sheet production needs.

Product Parameters

Package

25kg/bag, or it can be customized as per buyer's requirement.

1000kgs/pallet, or 1300kgs/pallet

![]()

![]()

Shipping Information

Our Factory and Workshop

![]()

![]()

![]()

Main Export Markets