Antistatic PP Raw Materials For Medical Device Packaging

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | SUGO |

| Certification: | ISO9001:2015; ISO14001:2015; ISO45001:2018 |

| Model Number: | K7116 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 200 kgs |

|---|---|

| Price: | USD/KG |

| Packaging Details: | 25Kg/Bag, 40 Bags/Pallet |

| Delivery Time: | 3-7 days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 1,300,000 Kgs |

|

Detail Information |

|||

| Density: | 1.15 Kg/cm3 | Surface Resistance: | 10E9 |

|---|---|---|---|

| Bending Strength: | 25 Mpa | Molding Shrinkage: | Water Absorption |

| Water Absorption: | 0.12% | Application: | Medical Device Packaging |

| MOQ: | 1000 Kgs | Package: | 25 Kg/bag, 1000 Kgs/ Pallet |

| Company Style: | Manufacturer | Export Area: | Thailand, Malaysia, SIngaport, USA, Holland, France And So On |

| Highlight: | Antistatic PP Raw Materials,Medical Device Packaging PP Raw Materials,Antistatic Raw PP |

||

Product Description

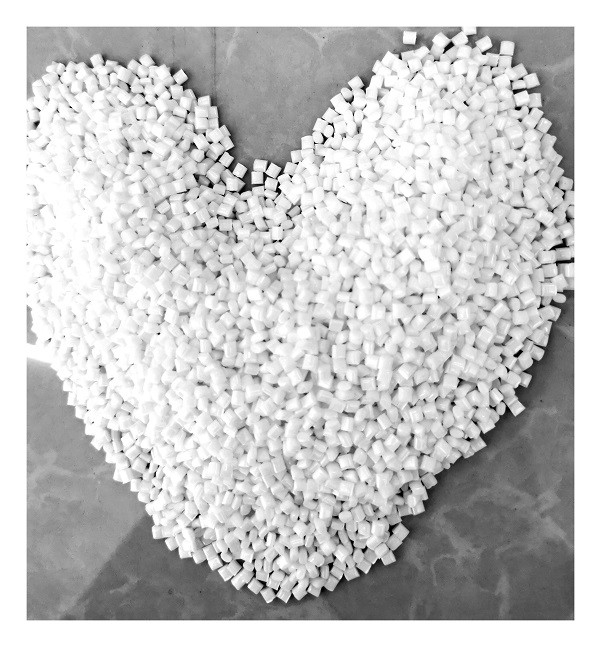

Anti-Static PP Raw Materials Used For Medical Device Packaging

Almost devices used in Medical field are very expensive, also very sensitive against

Electro-static Discharge, with ESD Protection, their designed functions will be destroyed

at certain degree during transportation.

However, This issue can be proper solve with our Anti-Static PP Raw Materials package.

The Monthly capacity of our factory for this kind of plastics granule is about 1,300,000Kgs.

| Raw Materials Technical Data | ||||

| Performance of the project | Test Method | Test Data | Data Unit | |

| Basic performance | Water Absorption | ASTM D-570 | 0.12 | % |

| molding shrinkage | ASTM D-955 | 1.2 | % | |

| density | ASTM D-792 | 1.15 | g/cm3 | |

| Mechanical Property | Tensile strength | ASTM D-638 | 17 | Mpa |

| elongation at break | ASTM D-638 | 12 | % | |

| bending strength | ASTM D-638 | 25 | Mpa | |

| flexural modulus | ASTM D-790 | 851 | Mpa | |

| notch impact strength | ASTM D-256 | ‘8 | KJ/M2 | |

| Behaviour of electricity | Volume surface resistivity | ASTM D-257 | ’10E9 | Ω |

| Thermal properties | distortion temperature | ASTM D-648 | 171-204 | ℃ |

| Drying Tempreture | - | 75 | ℃ | |

Please refer to below for parts of our production line:

![]()

![]()